Denowatts includes ISO/IEC Accredited Capacity Testing as part of the standard service

What is a Capacity Test?

The Denowatts Capacity Test measures the actual power rating of a photovoltaic array. This test is performed over a period of at least three sunny days using Deno simulators and the site power meter(s). A capacity test is typically required at the completion of construction, but is useful throughout the lifecycle of the project.

The Denowatts Capacity Test has three main benefits over traditional approaches:

- Lower Uncertainty. Using ISO 17025 Accredited calibrated sensors, the results are shown in the context of both ASTM and IEC reference standards against up to three energy models, reassuring the performance validity.

- Faster. Complete set-up time is about 2 hours, and high-resolution edge computing minimizes the need to filter out relevant data points, landing at results days or weeks faster that traditional test procedures.

- More Cost Effective. The Capacity Test Report is included with the Denowatts Benchmarking and Analytics Service and can be run as many times as needed with the click of a button.

What are the Reference Standards?

The Capacity Test includes both ASTM E2848 (2013) and IEC 61724-2 (2017) reference standards with respect to the customer-supplied energy model. These two reference standards use different approaches to arrive at similar results.

The ASTM method utilizes a multiple linear regression comparison of measured to expected power results. This reference standard was introduced in 2013 and is most widely-adopted.

The IEC method utilizes a non-regression comparison of measured to expected power. This reference standard was introduced in 2016 and is the most defined testing methodology.

Both tests have their strengths and weaknesses, so producing the results from both ensures the confidence in the results.

How does the Denowatts Capacity Test incorporate multiple Energy Models?

In addition to showing the test results against the ASTM and IEC reference standards, Denowatts shows the results against up to three different energy models. For example, using customer-specified parameters from a PVSyst model, Denowatts creates a PlantPredict model and a Denowatts model. Since each software program has a slightly different approach to the science of modeling, showing the results side-by-side provides additional confidence and validity in the final result.

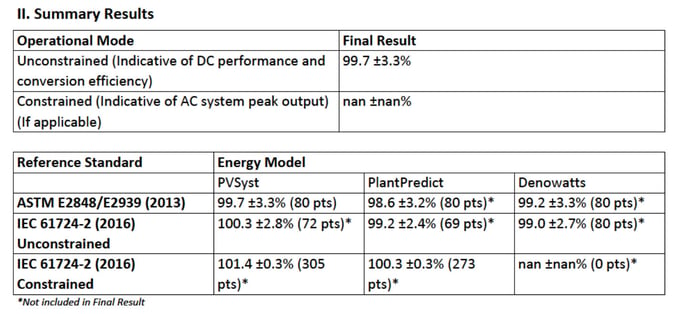

Capacity Test Results

The final result of the Denowatts Capacity Test is shown as both Unconstrained and Constrained operation. Unconstrained results are computed as the average of all energy models and reference standards, along with an expanded uncertainty (k=2). Many customers may additionally wish to see the Constrained results, which are only defined under the EIC reference standard. While these results may not always be available due to seasonal conditions, sites that are designed to frequently clip such as trackers and high load ratios will benefit from the constrained results.

The test report does not show Pass/Fail since this is typically determined by the counterparties technical and legal interpretation of the Denowatts results.

Capacity Test Steps

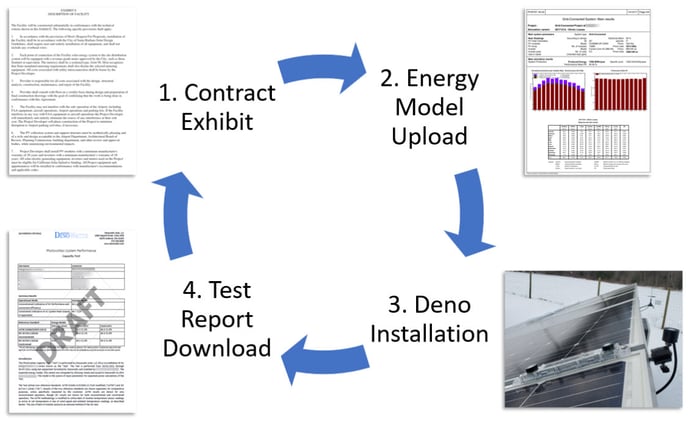

There are four steps to setting up for a successful Denowatts Capacity Test:

Step 1: Contract Exhibit

Step 2: Energy Model Upload

Step 3: Deno Simulator Installation and Commissioning

Step 4: Test Report Download

Each step includes a linked guide to walk you through the process. If you have any further questions please don't hesitate to contact us at support@denowatts.com or 978.309.6688