How does Denowatts benchmark bifacial modules?

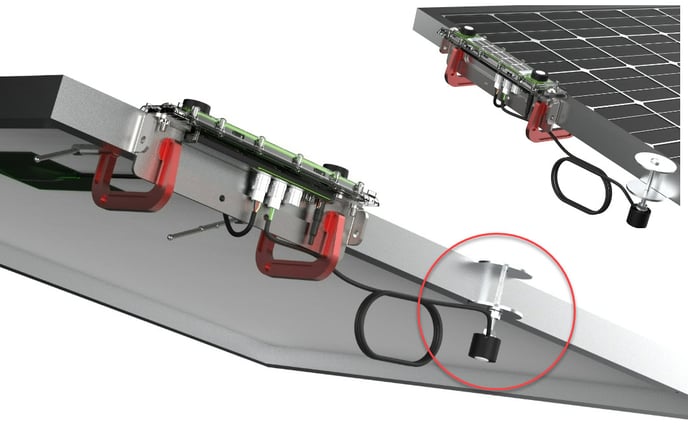

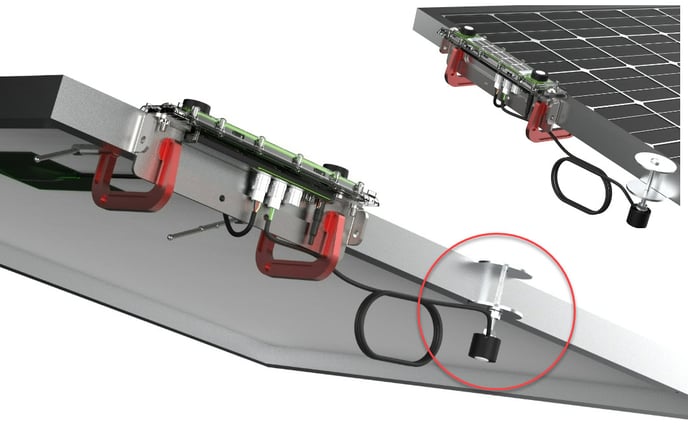

Deno benchmarking technology incorporates rPOA sensors and coding to accurately benchmark bifacial modules.

Bifacial Mode Overview

In March 2021 Denowatts released a bifacial benchmarking mode for its Deno simulators. Starting with model v3.13, users may use the auxiliary sensor to measure reverse plane of array (rPOA) irradiance.

When running in Bifacial mode, the irradiance measurements from the front and back sides will be summed together and reported as the effective irradiance on the array. Further, the expected and compared energy calculations performed by the Deno simulator will include both front and back readings.

Let's take a closer look at the science behind benchmarking bifacial modules and how Denowatts delivers a simple solution.

Understanding the science of benchmarking bifacial modules

Bifacial modules have seen increasing deployments over the past several years and are offered by many manufacturers alongside their monofacial cousins. Bifacial deployments are currently estimated at 20% of the total market and forecasted to dominate installations by 2030.

First, a quick review of the science. Bifacial modules incorporate cells with contacts and bus circuitry on both sides, utilizing either transparent backsheets or dual glass designs. Manufacturers report on the total efficiency of their modules including a "Bifacial Factor", which simply means the ratio of power conversion efficiency of the backside to the front side. For example, a module with a Bifacial factor of .74 will produce 74% of the amount of power from the back side of the module as the front side under the same standard test condition (STC).

The higher the tilt angle, elevation above the surface, reflectivity of the mounting surface, the more back side power contribution. Though this is highly dependent on the actual installation, in practice sites utilizing bifacial modules often yield 2-8% more energy than monofacial sites.

Next, let's look at how energy models calculate bifacial output.

Bifacial Energy Modeling

All major energy modeling software includes bifacial simulation options. While the science of constructing the model is quite complex, we can summarize it this way:

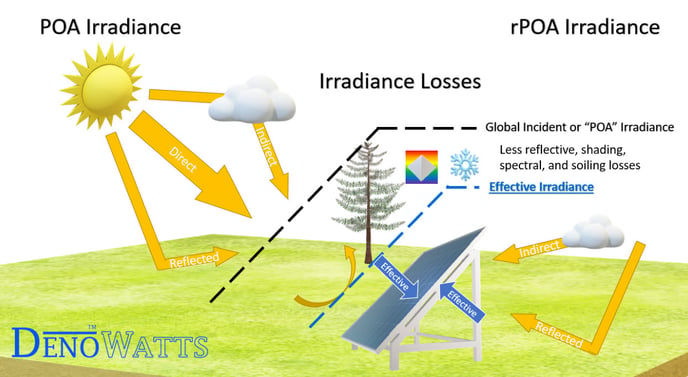

Electrical performance modeling begins with the effective, or absorbed, irradiation on the module.

- In the case of monofacial modules, the effective irradiance is from direct, indirect, and reflected light on the front side of the module.

- In the case of bifacial modules, the effective irradiance is from both the front side light components (direct, indirect, and reflected) as well as the back side indirect and reflected light components. Performance from the back side is further multiplied by the manufacturer's listed Bifacial Factor resulting in the aggregate energy yield from both sides.

If you would like to understand more details, please see the documentation available for your energy modeling software. Also here's a link to a comprehensive, ongoing study with some great information about measured results.

Next, let's understand how Denowatts makes benchmarking sites with bifacial modules simple.

Deno Bifacial Mode

Deno technology has a simple and effective solution for benchmarking bifacial modules. When configured in Bifacial Mode, the Deno simulator will add the irradiance measurements from both the Deno (POA) sensor and Auxiliary (rPOA) sensor. The rPOA measurements will additionally be adjusted by the manufacturer's Bifacial Factor. The result is the aggregate POA/rPOA value (aPOA) irradiance.

aPOA=POA + rPOA*BF

The aPOA values are processed and reported in Denowatts as Effective Irradiance. Further, aPOA is available in the POA modus registers and API calls for monitoring companies.

Finally, the aPOA values are used in the Deno simulator Expected and Compared Energy calculations. Using the same methodology of the energy model, the aPOA readings, along with temperature and static/dynamic factors, are computed in real time on the Deno simulator. These calculations are made in daytime every 5 seconds and formed to 1-minute records.

The result is a high resolution Expected Energy benchmark that utilizes edge computing to simplify bifacial computation and reduced data footprint.

Edge computing, sometimes called "fog" computing in IoT context, is pushing computation and data processing out to the device level. Processing data locally in the "fog" significantly reduces the data traffic to the cloud while increasing the processing frequency. This is especially important in computing Expected Energy due to the effect of constantly varying irradiance and temperature. The result is a more accurate benchmark with lower data and cloud costs.